Anycubic 405nm High Clear Resin For LCD 3D Printer

SPECIFICATIONS

Brand Name: ANYCUBIC

Form: Liquid

High-concerned Chemical: None

Warranty: 1.5 years

Color: High Clear

Wavelength: 365-405nm

Surface hardness: 78 HS

Compatibility: LCD DLP

High Clear Resin

Crystal and Clear

Resist Yellowing | Highly Transparent | Tough and Resilient

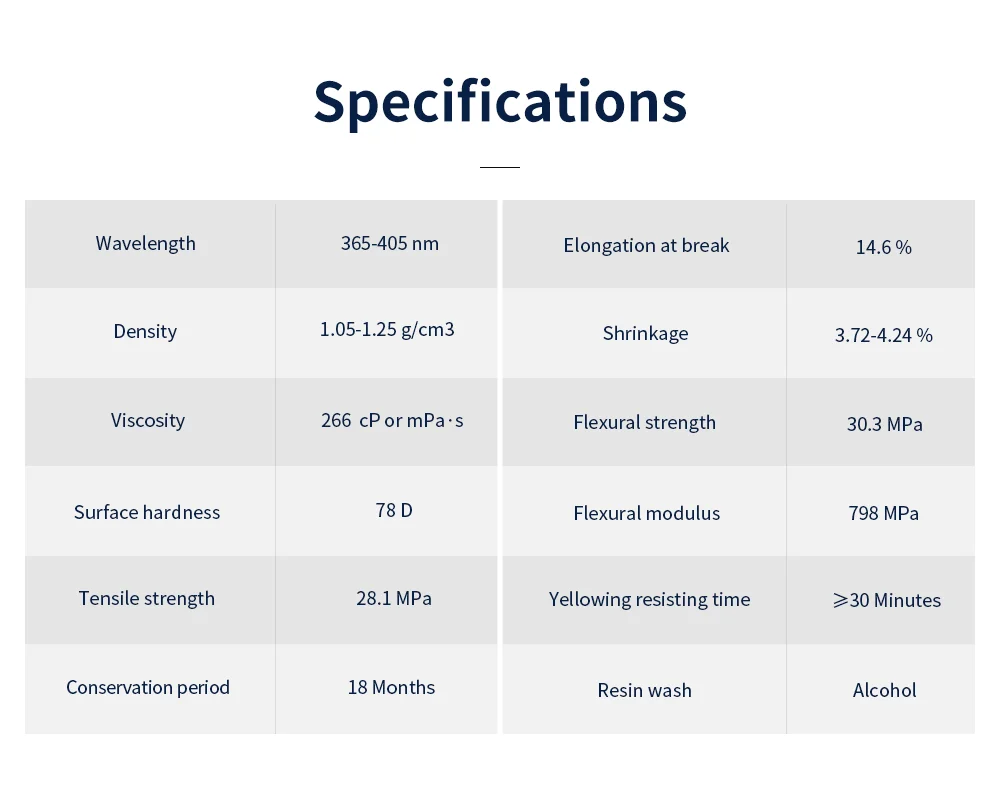

Specifications

Wavelength365-405nm Elongation at break 14.6%

Density 1.05-1.25 g/cm3 Shrinkage 3.72-4.24%

Viscosity : 266 cPormPa·s Flexural strength 30.3 MPa

Surface hardness 78 HS Flexural modulus 798 MPa

Tensile strength 28.1 MPa Yellowing resisting time >30 Minutes

Conservation period 12 Months Resin wash Alcohol

Yellowing degree test

Highly Transparent and Long-lasting Clarity

Model Varnishing

1. Model support removal

2.Alcohol wash

3.Apply High Clear Resin/varnish

4.Cure for 2 minutes

Tough and Resilient

A 100% rise in resilience compared to standard resin,

making the prints and models less easy to break.

Light Odor and Safe

The High Clear Resin has a light odor and is less irritating ,

bringing users a better and safer printing experience.

Recommended Printing Parameters

To ensure outstanding clarity and transparency of the models,please reset the light exposure parameter.

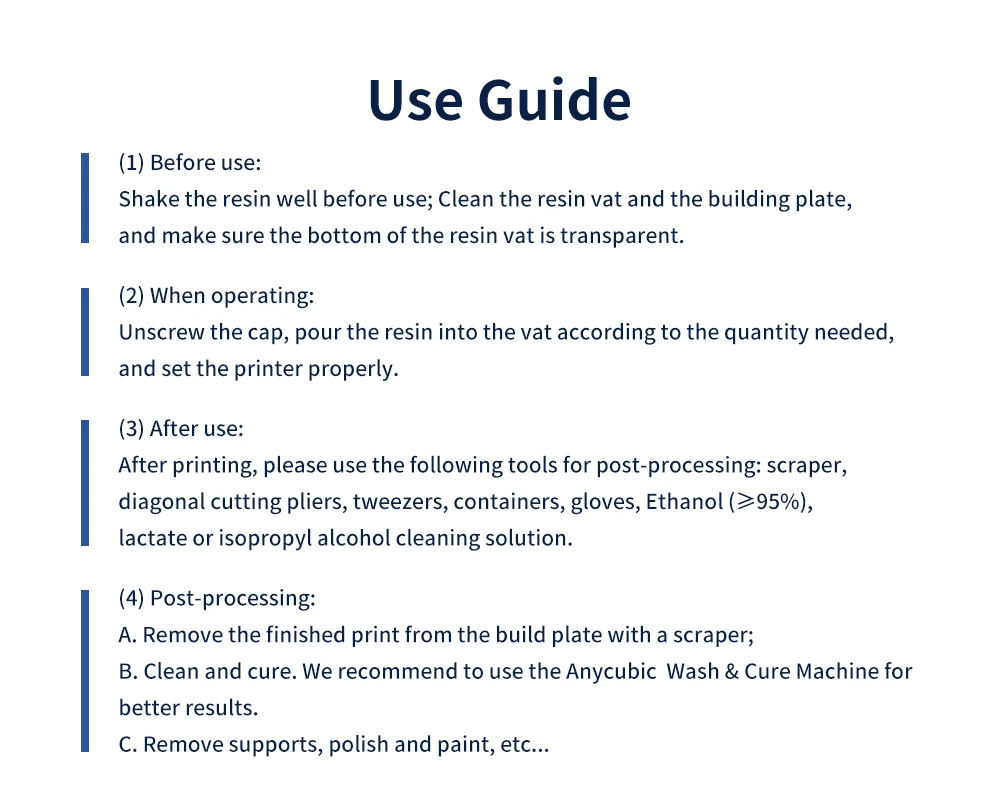

Use Guide

(1) Before use:

Shake the resin well before use;

Clean the resin vat and the building plate, and make sure the bottom of the resin vat is transparent.

(2) When operating:

Unscrew the cap, pour the resin into the vat according to the quantity needed, and set the printer properly.

(3) After use:

After printing, please use the following tools for post processing: scraper, diagonal cutting pliers, tweezers, containers, gloves, Ethanol (≥95%), lactate or isopropyl alcohol cleaning solution.

(4) Post-processing:

A. Remove the finished print from the build plate with a scraper;

B. Clean and cure. We recommend to use the Anycubic Wash & Cure Machine for better results.

C. Remove supports, polish and paint, etc...

Precautions

1 Store at room temperature, keep sealed and away from light. Avoid heat and direct sunlight.

2 Suggested storage temperature: 18-35℃.

Lowtemperatures might affect the printing results. The resin can be preheated (no more than 60C) before use. In case ofresin pigment settlement, please stir or shake well before use.

3 To ensure the best properties of the cured models, remember to control

the intensity and the exposure time of the light source.

To ensure the ideal curing material performance, the post-curing light intensity and time need to be controlled as suggested:

(1) The intensity of lamps or LED light source should not exceed 5-10mW/cm² and the exposition time should not exceed 1 hour (self-regulation);

(2) Close range exposure or prolonged exposure under strong light sources such as high power and high voltage lamp is prohibited.

(3) It is recommended to print in a dark room or put on the cover when printing.

Material performance may vary and is subject to the machine used and

post-curing technique. Please refer to the product MSDS for safety information. If you have any problems or questions, please feel free to contact us.